Introduction to Steel Manufacturing

Steel manufacturing is a cornerstone of modern industry, playing a pivotal role in the construction, automotive, and machinery sectors. As a material, steel is celebrated for its durability, versatility, and cost-effectiveness. The process of transforming raw materials into steel involves several stages, including smelting, refining, and alloying, each contributing to the final product’s characteristics. Understanding the intricacies of steel manufacturing provides insight into its economic and environmental impact, as well as its potential for future innovation.

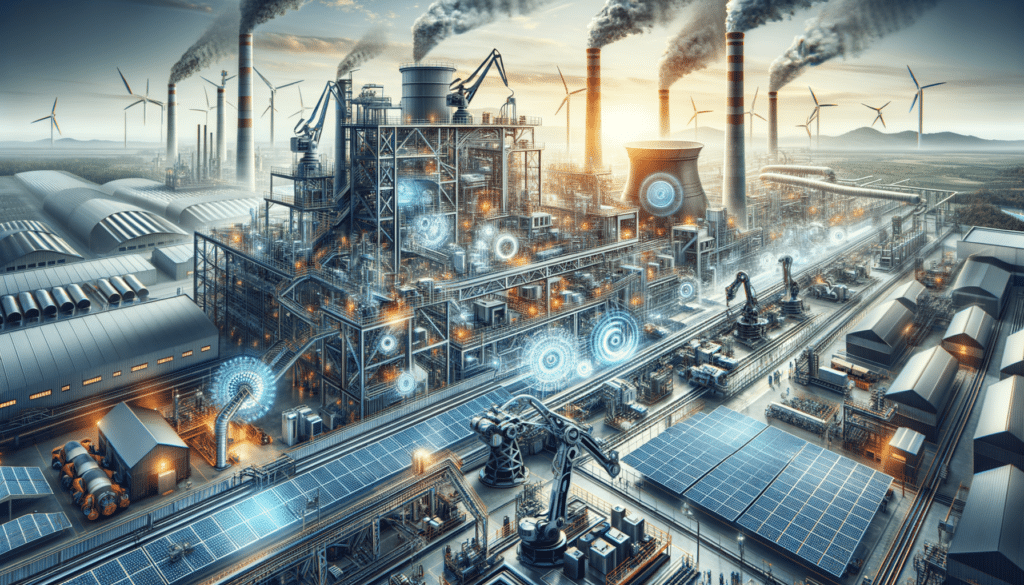

Technological Innovations in Steel Production

The steel industry has witnessed significant technological advancements over the past few decades. These innovations aim to improve efficiency, reduce costs, and minimize environmental impact. Some of the notable advancements include:

- Electric Arc Furnaces (EAFs): These furnaces offer a more energy-efficient method of steel production compared to traditional blast furnaces.

- Continuous Casting: This process enhances the quality and consistency of steel products while reducing waste.

- Advanced Metallurgy: New alloying techniques have led to the development of high-strength, lightweight steels suitable for various applications.

These technologies not only optimize production processes but also contribute to the industry’s sustainability goals by reducing carbon emissions and energy consumption.

Sustainability and Environmental Impact

The steel industry is increasingly focused on sustainability, driven by regulatory pressures and consumer demand for environmentally friendly products. Efforts to reduce the carbon footprint of steel manufacturing include:

- Recycling: Steel is one of the most recycled materials globally, with a recycling rate of over 85%.

- Emission Reduction: Innovative technologies, such as carbon capture and storage (CCS), are being explored to mitigate greenhouse gas emissions.

- Energy Efficiency: Implementing energy-efficient practices and renewable energy sources in production facilities.

These initiatives demonstrate the industry’s commitment to balancing economic growth with environmental responsibility.

Economic Significance of the Steel Industry

The steel industry is a vital component of the global economy, providing millions of jobs and contributing significantly to GDP. Its products are essential for infrastructure development, transportation, and manufacturing. Key economic impacts include:

- Job Creation: The industry supports a vast network of direct and indirect employment opportunities.

- Trade: Steel is a major traded commodity, influencing international trade dynamics.

- Innovation: Investments in research and development drive technological advancements and economic growth.

The steel sector’s economic contributions underscore its importance in shaping modern society and driving future progress.

Future Trends and Challenges

Looking ahead, the steel industry faces both opportunities and challenges. Emerging trends include:

- Green Steel: The development of low-carbon steel production methods is gaining momentum.

- Digitalization: The integration of digital technologies, such as AI and IoT, is transforming production processes.

- Global Competition: The industry must navigate competitive pressures from emerging markets.

Addressing these challenges requires strategic planning, investment in innovation, and collaboration across the supply chain. The industry’s ability to adapt and evolve will determine its success in a rapidly changing global landscape.